In many sectors, attachment changeover on hydraulic equipment is a procedure that takes place several times during a working day. Carrying this out rapidly and without the use of tools is key in maintaining high levels of productivity.

In many sectors, attachment changeover on hydraulic equipment is a procedure that takes place several times during a working day. Carrying this out rapidly and without the use of tools is key in maintaining high levels of productivity.

In addition to accomplishing changeover procedures quickly, there should be no fluid leakage which would make the working environment contaminated and unsafe. This is why quick couplings use internal mechanisms that guarantee the seal once they are uncoupled.

The oil moves in a smaller space in these connection areas and is constrained to flow around these components. There is also a pressure drop, commonly termed load loss – this phenomenon is inevitable if the versatility of an interchangeable circuit is required. The manufacturer of the quick couplings, therefore, bears the responsibility to provide hydraulic solutions to take these into account.

Stucchi Delivers Pressurized Quick Connect Solutions

Stucchi has been one of the leading worldwide manufacturers of quick couplings for handling pressurized fluids since 1960. For 60 years, we have been providing continual product innovation for the market and improving quality as a result of our dedication to research and development. We carefully assess each choice related to the design, components and mechanisms of our quick couplings. This minimizes load losses more effectively compared to other options available on the market.

The value provided by quick couplings, however, is not absolute. The characteristics of the circuit in which it will be used will also have to be considered when choosing the most appropriate quick couplings. One of the key factors is the size of the hydraulic fitting compared to that of the pipe.

If the quick coupler is too small, the quantity of fluid will be excessive for the coupling. This high degree of forceful channeling causes greater load loss and a reduction in the performance of the machinery (slower motion). In the most extreme cases, the circuits overheat beyond their limits causing damage to the components, which are not designed to support these types of operating conditions. This compromises the functionality of the entire system.

By contrast, an oversized quick coupling will not suffer from these problems, but it will cause excessive clutter in many operating environments. A quick coupler that is too large may also cause inconveniences or inefficiencies as well as higher costs.

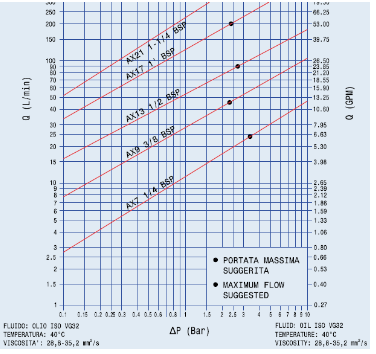

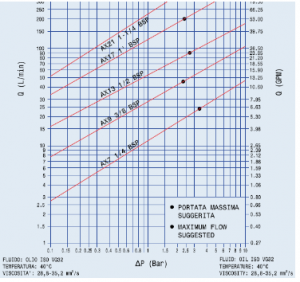

For these reasons, a load loss table provides fundamental information in choosing the most suitable quick coupling.

- the vertical axis displays the flow rate of the hydraulic system;

- from here, it runs horizontally until it crosses one of the red lines, which represent the recommended quick coupling models;

- the black dots indicate their maximum flow rate, so if the flow rate of the system is higher, that particular quick coupling should be excluded;

- at the point of intersection, the load loss is obtained by dropping down vertically to the reading on the horizontal axis.

The size of the quick coupling can thus be immediately identified based on the estimated load loss.

Stucchi offers quick connect solutions for a wide range of industries, including highly pressurized processes. We design, engineer and manufacture quick couplings with careful evaluation of all considerations, including load loss. Contact us to find out more about Stucchi solutions for handling pressurized flows.

This post first appeared here: https://www.stucchigroup.com/en/how-to-choose-a-quick-coupling-for-optimal-performance/