Stucchi offers industry-specific solutions with resources and information on a variety of market applications. Our video Application Insights – Improve Die Changeover Time in Die Casting shows operators in the molding and diecasting industries quick connect techniques that significantly improve productivity.

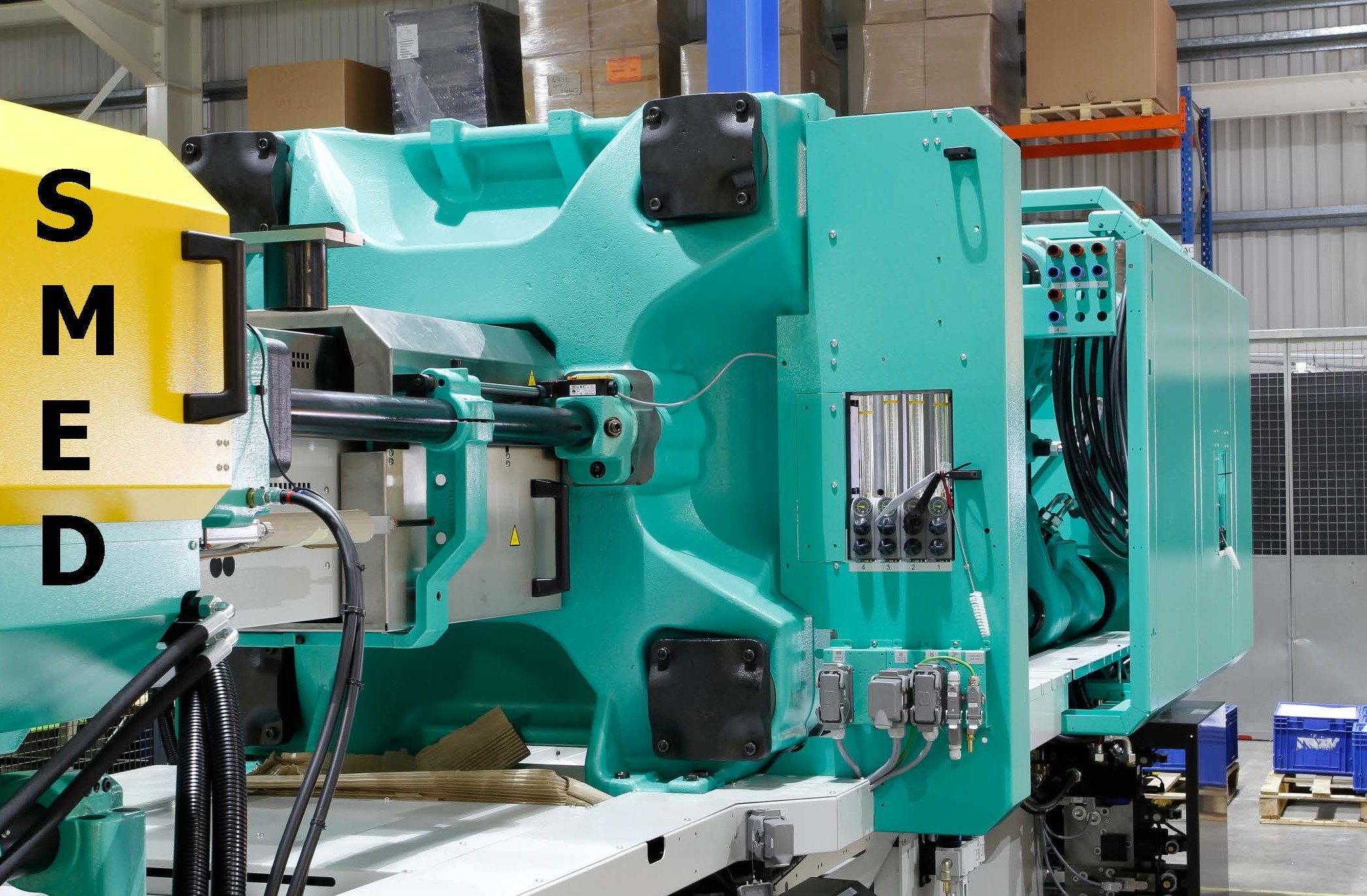

Stucchi’s quick-release couplers and multi-coupling plates support Single Minute Exchange of Dies, SMED, and continual improvement initiatives with quick mold change solutions.

SMED Supports Lean Manufacturing

Stucchi shows you firsthand in this quick video how our quick connect solutions improve die changeover time. SMED is a goal of molders and die casters that contributes to lean manufacturing, improved productivity, and other benefits like improved safety. SMED supports lean manufacturing, eliminating waste by reducing tool changeover time to less than 10 minutes (single digits), thus maximizing press uptime.

Stucchi shows you firsthand in this quick video how our quick connect solutions improve die changeover time. SMED is a goal of molders and die casters that contributes to lean manufacturing, improved productivity, and other benefits like improved safety. SMED supports lean manufacturing, eliminating waste by reducing tool changeover time to less than 10 minutes (single digits), thus maximizing press uptime.

SMED, combined with a progressive, predictive maintenance program, allows for reduced changeover time to support lean, just-in-time manufacturing, reducing inventory and increasing productivity and profitability. SMED and mold changeover time is a key performance indicator (KPI) of molders and die casters and one of the greatest goals in the die-casting industry.

Improve Die Casting Productivity

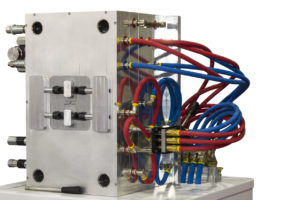

Stucchi offers quick connect solutions that bring value to die casting changeovers to help molders achieve SMED goals. Part of the die changeover process involves disconnecting the many heating and cooling lines that run through the mold. Depending on the size and complexity of the mold, there can be anywhere from 2 to 100 lines running through the mold. The die changeover involves disconnecting all of these lines to remove the existing mold and connecting all new lines on the newly installed mold.

Performing these line connections and disconnections as quickly and safely as possible is necessary to achieve SMED goals.

Consequences of Incorrect Manual Connections

Operators are under pressure to make connections quickly, which can lead to errors. Incorrectly connecting lines can have serious consequences, such as unplanned press downtime as well as running bad product. Press downtime and troubleshooting connections can cost companies thousands of dollars per hour in wasted press time. Running scrap product can be just as costly and damage a business relationship if bad product makes it to the customer.

Stucchi’s Die Casting Tool Changeover Solutions

Stucchi offers quick-release couplings and multi-coupling plates that simultaneously disconnect and connect multiple lines with one simple movement.

FIRG-Q Push To Connect Flat Face Coupler – The FIRG Q Series of flat face couplings features QPQ plating that provides superior corrosion resistance, ideal when working with water cooling lines. The FIRG Q Series can feature different seals for fluid compatibility and various operating temperatures.

VEP Thread to Connect Flat Face Coupler – Thread to connect coupler with patented internal valve prevents premature wear in applications with trapped pressure and pressure impulses. Flat face design eliminates fluid leakage and contamination.

GR Multi-Coupling Plate – Simultaneously couple and uncouple 2 to 10 hydraulic and/or electrical lines with one simple movement.

GRE Multi-Coupling Plate – Connect 4 to 18 water, air, oil, and/or electrical lines simultaneously with little effort. Reduce downtime in die changeovers, production test benches, and electrical circuits. Prevent crossed lines and inversion of circuits.

Watch this video to see how easy it is to improve die changeover time with Stucchi quick couplings and multi-coupling plates.

VIDEO: Improve Die Changeover Time

Benefits of Stucchi Die Changeover Solutions

Stucchi’s quick-connect solutions for die changeovers help die casters and molders to achieve SMED initiatives and provide many benefits:

- Achieve SMED die changeover goals

- Reduce waste, increase press uptime

- Prevents incorrect line connection

- Eliminate troubleshooting and downtime

- Improve operator safety

- Leak-free connections improve safety and ergonomic movements

- Longer product life with heating and cooling mediums

Stucchi offers many product solutions to the Die Casting industry that improve productivity, profitability, and safety.

Stucchi is a leading global supplier of quick-connect solutions for hydraulic machinery and equipment and other connections requiring water, oil, and/or electrical lines. We offer industry-specific solutions with more than 60 years of experience in providing custom quick-connect products. Contact us to speak with a quick connect specialist to improve your die changeover time and achieve SMED and continual improvement goals.