Table of Contents

Modern agriculture demands fast and efficient equipment operations, including the ability to connect and switch implements quickly, minimize hydraulic fluid waste, and maintain systems that are safe and reliable. Flat-face hydraulic couplers for agricultural operations answer these needs with leak-free connections, easy tool-free coupling, and reduced contamination risk.

In this article, we’ll show you how flat-face couplers enhance agricultural productivity, with detailed insights and practical guidance on selecting the proper hydraulic fittings and preventing overheating in mobile and ag equipment.

Flat-Face vs. Poppet Couplers in Agriculture

In hydraulic systems, two common quick-attach styles dominate: traditional poppet (mushroom-head) couplers and the more advanced flat-face design.

In hydraulic systems, two common quick-attach styles dominate: traditional poppet (mushroom-head) couplers and the more advanced flat-face design.

- Tool-free connections – Flat-face couplers snap together with no wrenches required, ideal for quick implement swaps.

- Drip-free performance – Their flat sealing surfaces eliminate messy drips, protecting both equipment and valuable crops from contamination

- Heat and pressure resilience – Flat-face designs handle thermal expansion and high-pressure spikes more effectively than poppets, making them particularly useful during extended runs or when storing hot equipment.

By halting fluid loss and reducing the likelihood of leaks, flat-face couplers offer significant benefits, including cost savings and time efficiency, which are crucial in agriculture where equipment efficiency and environmental safety are top priorities.

ISO 16028: The Gold Standard for Flat Face Hydraulic Couplers

ISO 16028 establishes the global dimensional and performance standard for flat-face hydraulic couplers, defining critical specifications to ensure leak-free, safe, and efficient performance in demanding applications. This standard ensures:

- Global interchangeability: Couplers fit and function reliably across equipment brands and models.

- Leak-free operation: Engineered for clean connections and disconnections, even under high pressure.

- Contamination control: The flat face design prevents debris ingress, protecting the hydraulic system’s integrity.

ISO 16028-certified couplers provide consistent performance and compatibility, making them ideal for use in agriculture and other high-demand industries. Learn more about how Stucchi’s flat face coupler design set the ISO 16028 industry standard.

How Flat Face Hydraulic Couplers Work to Improve Ag Operations

Flat-face hydraulic couplers play a crucial role in agricultural equipment, where clean, efficient, and safe hydraulic connections are vital for maintaining optimal performance in demanding conditions. Their design addresses frequent attachment changes, exposure to dirt and debris, and the need for fluid conservation.

- Connection – Flat face couplers securely link two hydraulic lines by aligning smooth, flat mating surfaces, ensuring a secure connection. This flat-face interface provides a uniform, tight seal with no cavities or protrusions that could trap debris or allow fluid leaks. The design promotes easy alignment and positive engagement for fast, reliable connections in the field.

- Sealing Mechanism – Precision-engineered O-rings and sealing surfaces within the coupler create a robust hydraulic seal. This prevents hydraulic fluid from escaping even under high-pressure conditions common in agricultural operations, maintaining consistent system performance and reducing the frequency of maintenance.

- Disconnection – During disconnection, flat face couplers contain residual fluid within the system. The flush face prevents drips and spills, reducing the risk of contamination and protecting soil, equipment, and operators from exposure to hydraulic oil.

Top Stucchi Flat Face Couplers for Agriculture

Selecting the correct flat-face hydraulic coupler for reliable performance in agricultural environments is essential where equipment must handle frequent attachment changes, exposure to dirt and moisture, and high-pressure demands. Stucchi offers several flat face coupler series engineered for durability and efficiency:

Selecting the correct flat-face hydraulic coupler for reliable performance in agricultural environments is essential where equipment must handle frequent attachment changes, exposure to dirt and moisture, and high-pressure demands. Stucchi offers several flat face coupler series engineered for durability and efficiency:

- A Premier & FIRG Series: Ideal for tractors, sprayers, and utility equipment, these ISO 16028 flat-face couplers deliver excellent flow capacity, robust durability, and leak-free reliability.

- A ZN Series (Zinc-Nickel Coating): Designed for corrosion resistance, these couplers perform in harsh environments exposed to fertilizer, mud, and outdoor elements.

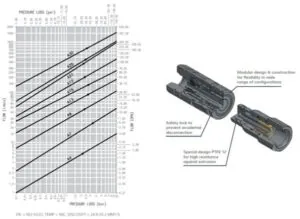

- APM Series with CUP Technology: These couplers enable secure manual connections under residual pressure, streamlining attachment swaps and minimizing downtime in the field.

In demanding agricultural applications, selecting the right flat-face hydraulic coupler ensures consistent performance, leak-free reliability, and efficient attachment changes. Stucchi provides hydraulic solutions specifically suited for tractors, sprayers, and implements operating in rugged conditions. Explore Stucchi’s Flat Face Couplers for detailed specifications and options specifically designed for mobile equipment and agriculture.

How Stucchi’s APM Flat Face Couplers Help Ag Processes

Stucchi’s APM series flat face hydraulic couplers offer enhanced functionality and durability, designed for demanding agricultural environments. Watch the APM Series video to see how this flat face coupling provides many benefits in addition to easy manual connection under pressure:

Stucchi’s APM series flat face hydraulic couplers offer enhanced functionality and durability, designed for demanding agricultural environments. Watch the APM Series video to see how this flat face coupling provides many benefits in addition to easy manual connection under pressure:

- The internal pressure release valve system allows safe, manual connection even when residual pressure is present.

- Valve design minimizes pressure drop, thereby preserving circuit efficiency and supporting the high-flow requirements of modern implements.

- Learn more about Hydraulic Pressure Drop, including how to estimate it and the consequences of pressure drop in hydraulic systems.

- Minimal fluid spillage during disconnection reduces environmental impact and cleanup time.

- Hardened surface areas reduce susceptibility to brinelling, extending service life.

- Superior resistance to pressure impulses ensures reliability even during repetitive coupling and uncoupling cycles.

These engineering features make the APM flat face hydraulic coupler a safe, simple, and effective choice for farmers and agricultural contractors looking for dependable, leak-free hydraulic performance. Learn more about How Flat Face Hydraulic Couplers Work and the benefits in agricultural processes.

How to Measure Flat Face Couplers

Accurate measurement is crucial when selecting flat-face hydraulic couplers to ensure compatibility, performance, and safety in demanding agricultural and industrial environments. Properly identifying the nominal size, body dimensions, and port threads prevents connection failures, leaks, and unnecessary downtime.

Key measurement steps:

- Measure body size: Use calipers or precision tools to determine the external body diameter.

- Measure port threads: Identify thread type and size—this ensures the coupler will mate properly with your equipment.

- Confirm nominal flow diameter: Ensure the selected coupler matches your system’s flow rate requirements.

Read our guide on How to Measure Flat Face Couplers

Beyond Measurement: What to Consider When Selecting Flat Face Couplers

1. Understand Port Thread Types

Even correctly sized couplers can fail if thread compatibility is overlooked. Common thread types include NPT, BSP, SAE, and metric threads. Matching thread types prevents leaks and ensures a secure hydraulic connection.

Learn more about Common Port Thread Types

2. Use the S.T.A.M.P. Method for Accurate Coupler Selection

Selecting a flat face coupler requires evaluating multiple criteria beyond size:

- S = Size: Confirm the correct size for flow requirements.

- T = Temperature: Match sealing materials to environmental and media temperatures.

- A = Application: Account for flow direction, impulse conditions, and external forces.

- M = Media: Ensure material compatibility with hydraulic fluids.

- P = Pressure: Verify working and burst pressure ratings meet system demands.

Using the S.T.A.M.P. Method to Select Proper Quick Couplings

3. Consider Working and Burst Pressure Ratings

Pressure ratings are crucial for ensuring the safety and optimal performance of hydraulic systems. Select couplers that meet or exceed your system’s operating pressures to prevent leaks, failures, and hazards. Undersized couplers can cause flow restrictions and overheating. It is critical to understand working and burst pressure ratings.

Pressure ratings are crucial for ensuring the safety and optimal performance of hydraulic systems. Select couplers that meet or exceed your system’s operating pressures to prevent leaks, failures, and hazards. Undersized couplers can cause flow restrictions and overheating. It is critical to understand working and burst pressure ratings.

Understanding Working and Burst Pressure Ratings

4. Consider Pressure Drop in System Design

Even properly sized couplers can reduce system efficiency if the pressure drop is not managed. Excessive pressure drop leads to slower response times, overheating, and reduced system life. Evaluating pressure drop ensures hydraulic efficiency under load.

Understanding Hydraulic Pressure Drop

Common Flat Face Coupler Sizes and Ag Applications

Flat face hydraulic couplers are available in a range of sizes optimized for various agricultural equipment and tasks:

| Coupler Size | Typical Application |

|---|---|

| 3/8″ | Compact equipment, light-duty agricultural attachments |

| 1/2″ | General-purpose hydraulics, skid steers |

| 3/4″ | Mid-size excavators, loaders, and attachments |

| 1″ | High-flow circuits, large construction machinery |

3/4″ flat-face hydraulic couplers are a popular choice due to their balance of flow capacity and versatility, making them ideal for mid-size agricultural equipment where performance and ease of connection are critical.

How to Connect Flat Face Couplers Under Pressure

Agricultural equipment often operates in demanding conditions, requiring frequent hydraulic implement changes throughout long field days. Residual hydraulic pressure trapped in lines after shutdown is a common challenge that makes flat-face couplers difficult to connect. Attempting to force connections under these conditions increases the risk of equipment damage, operator injury, fluid leaks, and costly downtime.

Stucchi’s CUP (Connect Under Pressure) Technology directly addresses this challenge. The APM Series flat-face hydraulic couplers incorporate a specialized triple-valve system that automatically relieves internal residual pressure. This enables operators to manually connect flat face couplers safely and efficiently, even when pressure remains in the hydraulic lines, without requiring external tools or excessive force.

Key advantages of Stucchi’s CUP Technology

Stucchi offers hydraulic coupling solutions for agricultural operations that provide:

- Safe manual connection under pressure: Eliminates delays and reduces operator fatigue during frequent implement changes.

- Leak-free sealing: Prevents fluid loss and protects the environment, minimizing soil contamination risks on the farm.

- Durable, long-lasting design: Reduces wear and protects seals, maintaining performance and extending equipment life.

By ensuring effortless and reliable connections, CUP-equipped flat face hydraulic couplers support uninterrupted workflows, improve safety, and protect equipment, making them ideal for modern agriculture where uptime and efficiency matter. Learn more about connecting flat face couplers under pressure.

Prevent Overheating in High-Flow Agricultural Applications

Mobile equipment used in land management tasks, such as mulching, is often equipped with standard OEM quick couplers, regardless of whether high-flow hydraulic couplers are necessary for the specific application. When operators attach implements, such as mulching heads, that require high-flow hydraulics, the equipment can overheat, shut down, or even pose a fire risk.

Mobile equipment used in land management tasks, such as mulching, is often equipped with standard OEM quick couplers, regardless of whether high-flow hydraulic couplers are necessary for the specific application. When operators attach implements, such as mulching heads, that require high-flow hydraulics, the equipment can overheat, shut down, or even pose a fire risk.

Many operators may not realize that their machinery is not properly equipped to handle the hydraulic demand of these tools. Without proper high-flow hydraulic couplers, the consequences include reduced productivity, increased maintenance, and potential safety hazards.

High Flow Hydraulic Couplers | Stucchi Mulching Solutions

Best Practices for Mini Excavator Attachments

Mini excavators equipped with auxiliary attachments, such as hydraulic thumbs, must carefully manage hydraulic flow and temperature to avoid inefficiencies and system stress. Using appropriate hydraulic quick couplers and monitoring fluid temperature ensures optimal performance while reducing wear on components.

Prevent Overheating with Best Practices for Mini Excavator Attachments

Prevent Skid Loader Overheating

Skid steers operating high-demand attachments, such as mulching heads, face similar risks of overheating. Following best practices for selecting high-quality couplers and maintaining hydraulic systems can help operators protect their equipment and maintain consistent productivity during intensive operations.

Prevent Skid Loader Overheating When Mulching

Leak-Free Tractor Hydraulic Fittings

Maintaining leak-free hydraulic connections is crucial for ensuring reliable and efficient performance in agricultural operations. Tractor hydraulics often endure demanding conditions—exposure to dirt, vibration, and frequent attachment changes—that can degrade seals and cause leaks over time.

Routine inspection and proper maintenance of hydraulic fittings help prevent downtime, protect system components, and reduce environmental impact. Selecting quality flat face couplers that minimize fluid loss during connection and disconnection is a key step toward achieving leak-free performance.

For best practices on maintaining hydraulic systems and ensuring leak-free operation on tractors, see Stucchi’s guide: Leak-Free Tractor Hydraulic Fittings.

Auxiliary Hydraulic Kits for Agricultural and Mobile Equipment

Stucchi offers a comprehensive range of Auxiliary Hydraulic Kits designed for excavators, mini-excavators, compact track loaders (CTLs), skid steers, and other mobile machinery used in agricultural and land management operations. These kits support seamless, reliable hydraulic performance by combining high-quality quick couplers, adapters, mounting brackets, conversion kits, and the Stucchi Saturn Block for efficient field replacement.

Stucchi offers a comprehensive range of Auxiliary Hydraulic Kits designed for excavators, mini-excavators, compact track loaders (CTLs), skid steers, and other mobile machinery used in agricultural and land management operations. These kits support seamless, reliable hydraulic performance by combining high-quality quick couplers, adapters, mounting brackets, conversion kits, and the Stucchi Saturn Block for efficient field replacement.

We provide brand-specific solutions tailored for manufacturers such as John Deere, Bobcat, ASV, and Takeuchi. Each kit is engineered for durability, compatibility, and simplified installation—ideal for enhancing performance, minimizing downtime, and extending equipment lifespan.

Explore Stucchi’s Auxiliary Hydraulic Kits for:

- Excavator and Mini Excavator auxiliary hydraulics

- Compact Tractor Loader (CTL) hydraulic kits

- Skid Steer auxiliary hydraulic kits

- Auxiliary hydraulic conversion kits

- Brand-specific solutions for popular OEMs

See available instructional resources to guide your installation and upgrade process:

- How to Convert a Takeuchi Skid Steer to Use Stucchi’s VEP Couplers

- How to Upgrade Your Bobcat 870 Skid Steer Auxiliary Hydraulics to Handle High Flow

Learn more or contact a Stucchi hydraulic specialist for assistance with selecting or customizing the right auxiliary hydraulic kit for your equipment.

Stucchi Hydraulic Solutions for Agricultural Applications

Flat-face hydraulic couplers have become the preferred connection solution in modern agriculture due to their performance advantages, including leak prevention, resistance to contamination, and ease of use. For operators managing frequent attachment changes and high-pressure hydraulic systems, selecting the right coupler is crucial for ensuring efficiency, equipment longevity, and minimizing downtime.

Stucchi offers an extensive range of flat-face hydraulic couplers, engineered for agricultural applications, with options including corrosion-resistant coatings and CUP technology for easy connection under residual pressure. Comprehensive technical resources and support from hydraulic specialists ensure that agricultural operators can select, measure, and maintain couplers that meet their exact requirements.

Stucchi offers industry-leading flat face couplers designed for reliable performance in demanding agricultural and mobile equipment applications. Our hydraulic specialists provide expert guidance to help you select the ideal couplers for your specific equipment and operating conditions. Contact Stucchi to speak to a hydraulic specialist about optimizing your agricultural equipment performance with Stucchi hydraulic solutions.