Table of Contents

Mobile and industrial equipment, from snow plows and excavators to injection molding machines, depend on fast, reliable hydraulic and electrical connections. Yet as systems evolve to handle multiple circuits for power, sensors, and control signals, operators face the same challenge: how to connect everything quickly, safely, and without mistakes.

Multi-coupling plate systems solve this by combining multiple hydraulic and electrical lines into a single, centralized connection point. Instead of wrestling with eight hoses and numerous plugs, one lever secures every connection in seconds, improving uptime, safety, and long-term reliability.

What Are Multi-Coupling Plate Systems?

Multi-coupling plate systems are engineered connection platforms that enable the simultaneous connection of multiple hydraulic, electrical, pneumatic, or auxiliary circuits through a single, guided interface. Rather than treating each line as a standalone connection, these systems enable OEMs and fleet operators to design equipment interfaces that prioritize repeatability, cleanliness, and operational efficiency.

This reduces operational variability across machines, operators, and environments. Depending on application requirements, multi-coupling systems can integrate:

- Multiple hydraulic circuits, including pressure, return, and case drain

- Electrical power and signal lines for controls, sensors, and feedback

- Pneumatic or water-glycol circuits

- High-flow and connect-under-pressure hydraulic applications

- Fixed, keyed layouts that physically prevent misconnection

When properly specified, multi-coupling systems become a foundational element in OEM tool carriers, industrial machinery, snow and utility fleets, mining attachments, and many other mobile and industrial equipment platforms where clean connections and repeatable performance are critical.

This system-level approach enables equipment designers to move beyond component selection and toward standardized connection architectures that support faster changeovers, cleaner operation, and long-term reliability across diverse operating environments.

The Operational Challenges with Conventional Couplers

As equipment evolves to support more functions, sensors, and control logic, traditional connection methods struggle to scale. Individually connecting hoses and plugs introduces risk, inefficiency, and inconsistency that compound across fleets.

Slow, Error-Prone Connection Processes

A single attachment may require six to twelve hydraulic lines plus electrical connectors. Connecting each circuit manually increases setup time and creates opportunities for:

- Incorrect hose routing

- Missed or partially seated electrical plugs

- Inconsistent startup performance

These delays may seem minor per connection, but they accumulate rapidly across daily changeovers, shift work, and seasonal operations.

Increased Risk of Fluid Loss and Contamination

Every manual hydraulic connection is a potential contamination point. Open fittings expose hydraulic systems to dirt, moisture, and debris, particularly in outdoor or industrial environments.

Repeated connections also increase the risk of:

- Seal damage

- Fluid drips or discharge during disconnect

- Environmental exposure and cleanup

For fleets and OEMs focused on reliability and compliance, uncontrolled fluid exposure undermines contamination control strategies and shortens component life.

Pressure and Electrical Integrity Challenges

Residual hydraulic pressure makes manual connections difficult and unsafe. Operators often resort to workarounds such as cracking fittings or applying excessive force, increasing the risk of fluid discharge and injury.

Electrical connectors present parallel challenges. Improper alignment or incomplete seating can result in intermittent signals, sensor faults, or control errors that are difficult to diagnose.

Lost Productivity Across Fleets and Production Lines

The combined effect of slow connections, misrouting, cleanup, and troubleshooting creates measurable productivity loss.

Across construction fleets, utility operations, plastics molding cells, mining equipment, and robotics applications, minutes lost per changeover translate into:

- Reduced machine utilization

- Increased labor cost

- Unplanned downtime

- Inconsistent performance across operators

These challenges explain why many OEMs and operators are actively seeking turnkey connection systems, not incremental component upgrades.

How Integrated Multi-Coupling Systems Solve These Challenges

Multi-coupling plates address these challenges by replacing connection complexity with engineered, guided engagement. Instead of assembling connections in the field, the system enforces correct alignment, sequencing, and lock-up by design.

One-Motion, Guided Engagement Architecture

Multi-coupling plates use a lever, cam, or mechanical assist to engage all circuits simultaneously. Alignment pins and fixed port layouts ensure proper positioning before connection occurs.

This dramatically reduces changeover time while eliminating connection variability between operators.

Built-In Error Prevention and Alignment Control

Keyed layouts and non-interchangeable port positions physically prevent cross-connection. Electrical and hydraulic lines cannot be mismatched, even in high-pressure or low-visibility environments.

This design-in error prevention removes a major source of startup failures and service calls.

Zero-Spill Connection and Contamination Control

When paired with flat-face coupling technology, multi-coupling systems support zero-spill connection and disconnection, protecting hydraulic circuits from contamination and fluid loss.

This improves cleanliness, reduces environmental exposure, and supports longer service intervals across equipment platforms.

Designed for OEM Integration and Customization

Unlike generic connector assemblies, integrated multi-coupling systems can be:

- Configured for specific pin layouts and media mixes

- Integrated into bulkhead or panel mounts

- Delivered with CAD models for design-in workflows

- Adapted for electrical and pneumatic pass-throughs

- Supported with prototype sampling and validation

This allows OEMs to standardize connection architectures across machine families while accommodating application-specific requirements.

Key Benefits of Integrated Multi-Coupling Systems for OEMs and Fleets

When multi-coupling plates are specified as part of a complete connection strategy, not as an afterthought, they deliver measurable operational and engineering benefits across the equipment lifecycle.

Faster Changeovers, Predictable Uptime, and Improved Workflow Efficiency

Integrated multi-coupling systems dramatically reduce attachment changeover time by consolidating multiple hydraulic and electrical circuits into a single, guided engagement. Instead of connecting individual hoses and plugs, operators engage one interface, reducing changeovers from minutes to seconds.

This one-motion connection approach eliminates many of the inefficiencies and risks associated with conventional coupling methods. Multi-coupling plates:

- Connect all required circuits simultaneously

- Prevent cross-connection errors through fixed, guided layouts

- Remove the need for manual alignment or repeated adjustments

- Deliver consistent connection speed regardless of operator experience

For fleets, production lines, and equipment platforms with frequent tool changes, these capabilities translate directly into higher machine utilization, reduced idle time during changeovers, and predictable, repeatable uptime across shifts.

Industrial field data and equipment integrator experience show that this level of connection efficiency supports SMED (Single-Minute Exchange of Dies), lean manufacturing initiatives, and continuous improvement programs by standardizing and accelerating setup workflows without compromising safety or system integrity.

Error Elimination by Design: Preventing Misconnections at the Source

When multiple hydraulic and electrical lines are connected individually, human error becomes unavoidable. Misrouted hoses, skipped connectors, and incomplete engagement under pressure can lead to equipment malfunction, troubleshooting delays, and component damage.

Multi-coupling plates virtually eliminate these risks by design. Keyed guide pins, fixed circuit locations, and non-interchangeable port layouts ensure every line mates only with its intended connection. The system cannot fully engage unless all circuits are correctly aligned, physically preventing misconnection rather than relying on procedural checks or operator judgment.

This design-in error prevention delivers measurable operational benefits:

- Eliminates downtime caused by cross-connected hoses or incomplete electrical connections

- Protects valves, sensors, and downstream components from damage at startup

- Improves first-engagement reliability, even under residual pressure

Because correctness is enforced mechanically, multi-coupling systems deliver consistent results across shifts, operators, and environments. This repeatability is especially valuable in applications where uptime depends on fast, accurate tool changes, including industrial manufacturing equipment, heavy machinery with multi-function attachments, municipal snow and mowing fleets, and other high-changeover operations.

The result is not just fewer errors, but predictable performance and reliability engineered directly into the connection system itself.

Zero-Spill Integration and Engineered Contamination Control

When paired with flat-face coupling technology, multi-coupling systems enable true zero-spill connection and disconnection, significantly reducing fluid loss and contamination risk at every changeover. Instead of managing leaks and debris after the fact, cleanliness and safety are designed directly into the connection interface.

This engineered approach supports measurable operational benefits:

- Cleaner hydraulic circuits and reduced exposure to debris

- Longer service intervals and improved component life

- Improved environmental and job-site safety

- Reduced cleanup time, fluid replacement, and maintenance costs

For OEMs and fleet operators, contamination control becomes a built-in system attribute rather than a reactive field issue. By minimizing exposure to open hydraulic circuits, multi-coupling systems also reduce the risk of operator contact with hot, pressurized fluid—an important safety consideration in mobile equipment and high-duty industrial environments.

This combination of zero-spill performance and contamination control aligns with Stucchi’s broader role as a solutions provider, delivering connection systems that protect uptime, improve productivity, and support long-term reliability across demanding applications.

Reliable, Repeatable Performance Across Operating Conditions

Multi-coupling plate systems deliver the same fully seated, fully locked connection every time the lever is engaged. This repeatability eliminates the variability common with hand-connected couplers, particularly when hoses are pressurized, misaligned, or difficult to access.

Mechanical locking mechanisms ensure consistent engagement across all circuits:

- Hydraulic lines seat fully and securely

- Electrical connectors lock with proper alignment

- Connection integrity remains stable under pressure spikes and vibration

- Each circuit performs as intended at startup

For operators and maintenance teams, this translates into fewer leaks, fewer intermittent electrical issues, and more predictable system behavior across demanding duty cycles.

That consistency becomes even more valuable across mixed fleets. Whether equipment is operated by different personnel, shared across job sites, or sourced from multiple manufacturers, standardized multi-coupling interfaces ensure uniform connection quality. This simplifies training, reduces troubleshooting time, and supports reliable operation in rental fleets, municipal and utility equipment, and mixed-generation or mixed-brand machines.

The result is not just a better connection, but a repeatable system architecture that supports uptime, safety, and long-term reliability at scale.

What Multi-Coupling Systems Do That Standard Connections Can’t

Multi-coupling solutions designed for simultaneous hydraulic and electrical connections combine all essential circuits into a single unified interface.

Instead of aligning a dozen fittings, the operator:

- Positions the attachment

- Inserts the plate

- Pulls a single lever

All hydraulic and electrical lines lock into place at once.

Industry-leading designs, like those used in OEM tool carriers, agricultural implements, industrial molding cells, and municipal snow fleets, share several essential features:

- Centralized multi-circuit interface (hydraulic + electrical + drainage or case-return lines)

- Lever- or cam-actuated locking mechanism that multiplies operator force

- Integrated pressure relief to support connect-under-pressure hydraulic circuits

- Anti-crossing design ensures every line connects to its correct port

- Robust alignment guides prevent pinching or misalignment

- Support for multiple media, including hydraulic oil, water glycol, air, and electrical power/signal

These systems dramatically reduce changeover time and eliminate the complexity and risks associated with individual couplers and connectors.

See how Stucchi’s multi-coupling plates support both hydraulic and electrical connections: Stucchi Multi-Coupling Plates.

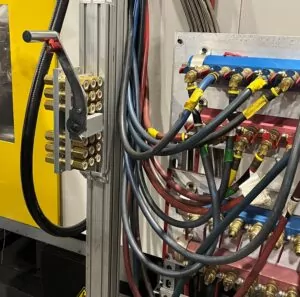

Stucchi Multi-Coupling Plate Lineup — Solutions for Hydraulic + Electrical Integration

Stucchi offers a comprehensive range of multi-coupling plates designed to support simultaneous hydraulic and electrical (or mixed-media) connections. Below is an overview of the plate series and their key use cases.

| Plate Series | What It Does / Key Features |

|---|---|

| Stucchi DP Plate Series | The DP plate enables the simultaneous coupling or uncoupling of 2, 4, or 6 hydraulic and/or electrical lines with a single, simple lever motion. It supports multiple media per connection (e.g. oil, water, low-voltage electrical), port sizes from 3/8″ to 1″, and is suited for applications needing quick connections under residual pressure. |

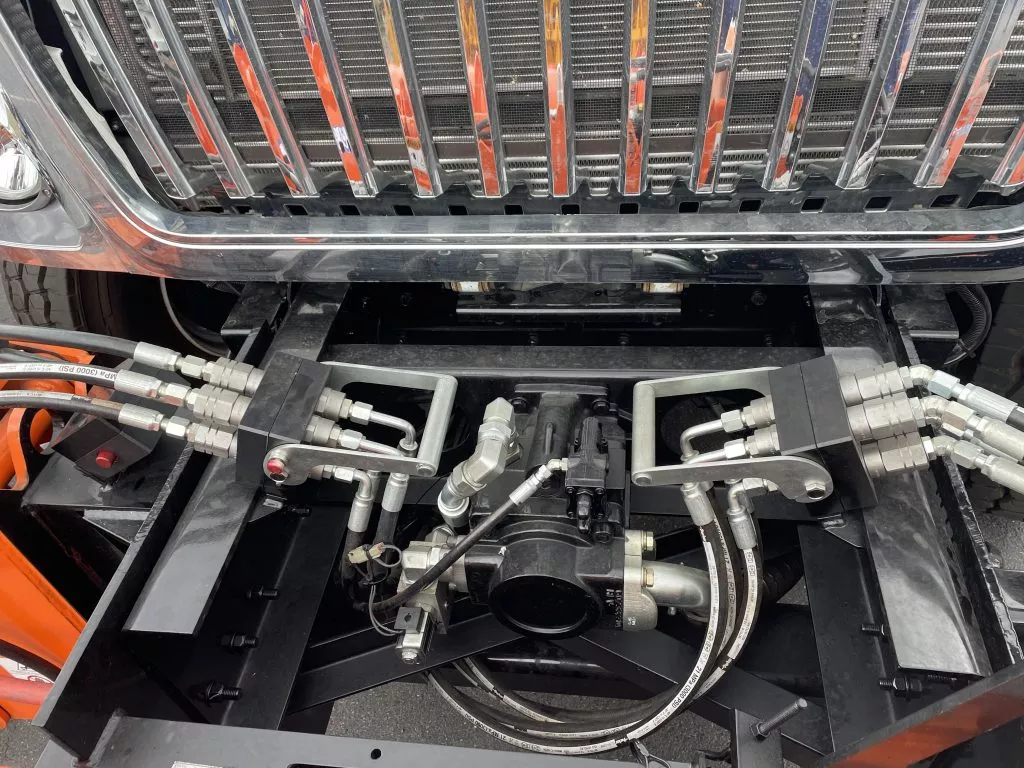

| GR Plate Series | GR plates allow 2 to 10 hydraulic/electrical lines to connect or disconnect at once with minimal operator force. Their auto-lock design prevents unintended disconnection, making them popular in mobile equipment, heavy machinery, snow-removal fleets, drilling rigs, and other applications requiring dependable multi-line hookups under pressure. |

| GRE Plate Series | The GRE plate series supports 4 to 18 circuits of mixed media — hydraulic oil, water, air, or electrical lines — making it ideal for industrial machines, test benches, die-casting, molding, or any complex equipment requiring water, oil, pneumatic, and electrical circuits simultaneously. It includes guidance pins to prevent circuit inversion (wrong hookup), ensuring consistent, error-free connections. |

| SV2 Plate Series | The SV2 plate is built for large-diameter hydraulic lines. It couples and uncouples two high-flow lines in a single motion, with an auto-locking system to ensure safe, secure connections. Common uses include mobile hydraulics, drilling and mining equipment, and heavy-duty implementations where quick yet robust large-line coupling is required. |

| BM3 Plate Series | BM3 plates also focus on two large-diameter hydraulic lines (e.g. pressure + return), enabling a simultaneous connect/disconnect with minimal effort. Their auto-lock feature ensures lines remain secured even under vibration or movement — ideal for heavy equipment and large-flow hydraulic systems. |

| One-Position Plate Series | Designed for single, large-diameter hydraulic lines, One-Position plates streamline connect/disconnect operations for high-flow attachments or systems needing straightforward, dependable hookups. They provide leak-free, quick coupling with auto-locking and repeatable performance. |

| FAP / FAPZ Replacement Couplers (for Multi-Plate Systems) | These are flat-face couplers designed to integrate with multi-coupling plates. They feature internal valve systems that allow safe connection even under residual pressure, while avoiding spills. The flat-face design supports leak-free connection/disconnection and improved contamination resistance. They are available in a range of port sizes and thread options, enabling retrofits or custom configurations. |

Multi-coupling plate series’ highlights:

- DP & GR plates — offer broad flexibility for moderate-circuit count setups (2–10 lines). Because they support electrical lines as well as hydraulic, they’re excellent for multi-function equipment — such as tool carriers, spreader-plow trucks, or snow-ice removal rigs.

- GRE plates — ideal for complex systems combining hydraulic, pneumatic, electrical, or water circuits, common in industrial manufacturing, test rigs, or multimedia equipment lines.

- SV2, BM3, One-Position plates — designed for heavy-duty hydraulic applications needing high flow/large diameter lines (plow trucks, snow/groomer equipment, drilling rigs, mobile hydraulic platforms).

- FAP/FAPZ couplers — critical for leak-free, pressure-resistant integration; they ensure that multi-line systems remain clean, safe, and reliable even under residual pressure or harsh environments.

How Stucchi Plates Support Mixed Hydraulic and Electrical Systems

- Stucchi multi-coupling plates can integrate hydraulic lines, electrical connectors, and even pneumatic or water circuits, enabling truly multi-media implementations.

- Auto-locking lever/cam systems reduce operator effort — one motion connects everything — and eliminate risk of cross-connection or misalignment.

- Flat-face couplers (FAP / FAPZ) combined with multi-plate design minimize fluid spillage, reduce contamination risk, and support connection under pressure — critical for industrial, mobile, or seasonal-demand applications (e.g. snow removal).

- Because Stucchi offers many plate sizes, port configurations, and media-type compatibility, these solutions can be customized or retrofitted for virtually any fleet or application.

When combined with auxiliary hydraulic kits, flat-face couplers, and connect-under-pressure technologies, multi-coupling plates become part of a turnkey connection platform rather than a standalone product.

This platform approach supports:

- Faster commissioning

- Reduced field rework

- Cleaner, safer operation

- Scalable deployment across machine families

For OEMs and fleet operators, it simplifies sourcing, integration, and long-term support.

Frequently Asked Questions: Designing with Multi-Coupling Systems

What types of circuits can be integrated into a multi-coupling plate?

Multi-coupling systems can integrate hydraulic pressure and return lines, case drain, electrical power and signal connections, pneumatic circuits, and water-glycol or auxiliary media, depending on application requirements.

Can multi-coupling plates support connection under residual pressure?

Yes. Many configurations incorporate connect-under-pressure technology, allowing safe, controlled engagement even when pressure is trapped in the system, without tools or fluid discharge.

Are multi-coupling plates suitable for harsh or outdoor environments?

Absolutely. When paired with flat-face coupling technology and proper sealing, multi-coupling plates are well suited for dusty, wet, high-vibration, and temperature-extreme environments common in construction, utilities, snow and ice management, mining, and industrial operations.

How customizable are multi-coupling plate systems?

Highly customizable. Layouts, port sizes, media types, electrical passthroughs, and mounting options can all be adapted to meet OEM or fleet-specific requirements.

When should OEMs involve Stucchi in the design process?

The earlier, the better. Engaging during concept or early design stages allows connection systems to be optimized for packaging, performance, cleanliness, and serviceability, reducing downstream costs and integration issues.

Stucchi’s Multi-Coupling Plate Summary

DP Series — High-Performance Multi-Circuit Connection

Self-aligning, lever-actuated multi-coupling plates designed for fast, repeatable changeovers.

GR Series — Connect-Under-Pressure Multi-Plate System

Operator-friendly cam-lever actuation with built-in CUP capability. Supports hydraulic + electrical circuits. How-to video: How to Connect and Disconnect the GR Series

GRE Series — Multi-Media Hydraulic, Pneumatic, & Electrical Plate

Engineered for mixed-media circuits (oil, air, water-glycol, electrical). Ideal for industrial automation and robotics.

SV2 Plate Series — High-Flow, Heavy-Duty Multi-Coupling

Built for large-diameter hydraulic circuits where high flow and robustness are critical.

BM3 Series — Auto-Locking Multi-Plate for Extreme Duty

Automatic locking for severe vibration, high-pressure impulses, and demanding work cycles.

One-Position Plates — Single-Point, Multi-Line Solution

A simple, compact solution to engage multiple lines in one position without a large plate block.

Replacement FAP & FAPZ Couplers – Drop-in couplers for multi-coupling plate maintenance and service.

Multi-coupling plates are the most reliable way to streamline workflows that require multiple lines or both hydraulic and electrical circuits to engage at once. Whether your equipment runs high-flow hydraulic lines, low-voltage control signals, air circuits, or multiple mixed-media channels, Stucchi offers one of the most complete, CUP-ready multi-coupling portfolios available. With fast, repeatable, one-motion operation and industry-proven durability, Stucchi helps operators work safer, faster, and with greater confidence, no matter how demanding the application.

Stucchi delivers engineered multi-coupling solutions that improve productivity, safety, and reliability in demanding hydraulic and mixed-media applications. We provide advanced coupling technologies, including connect-under-pressure systems and multi-circuit plates, to help operators achieve faster, cleaner, and safer equipment changeovers. Contact us today to explore multi-coupling solutions that support simultaneous hydraulic and electrical connections.