Table of Contents

- 1 Mini Excavator Attachments: Managing Hydraulic Heat for Peak Performance

- 2 Why Do Mini Excavators with Attachments Overheat?

- 3 Why Overheating Matters

- 4 Understanding Hydraulic Flow and Cooling Requirements for Mini Excavator Attachments

- 5 Best Practices to Prevent Overheating in Mini Excavator Attachments

- 5.1 1. Inspect and Maintain the Cooling System

- 5.2 2. Monitor Hydraulic Fluid Condition

- 5.3 3. Match Attachments to the Machine’s Flow and Pressure Ratings

- 5.4 4. Upgrade Quick Couplers for High-Flow Applications

- 5.5 5. Keep Hoses and Seals in Good Condition

- 5.6 6. Clear Dirt and Debris Frequently

- 5.7 7. Operate with Ambient Conditions in Mind

- 6 Hydraulic Solutions to Prevent Overheating in Mini Excavator Attachments

- 7 Connect-under-pressure (CUP) Solutions

- 8 Keep Your Mini Excavator Attachments Running Cool

Operating compact equipment like mini excavators, skid-steer loaders, and compact track loaders requires more than just skill at the controls; it demands diligent maintenance and a clear understanding of your machine’s hydraulic system.

Mini excavators are capable of impressive power for their size, but running high-demand attachments such as mulchers, stump grinders, and heavy-duty brush cutters can push hydraulic and engine systems to their limits. This strain often leads to overheating and accelerated equipment wear.

Excavator overheating is a common problem that, if left unchecked, can lead to costly engine damage and downtime.

Mini Excavator Attachments: Managing Hydraulic Heat for Peak Performance

Overheating in compact equipment is one of the most common challenges operators face when mini excavator attachments are pushed beyond their design capacity. Knowing how these systems work, why heat builds up, and the steps to keep temperatures under control is essential for safe, efficient operation. In this guide, we’ll break down the causes of overheating, outline best practices to prevent it, and show how Stucchi quick couplers and auxiliary hydraulic kits can help keep your machine and your productivity running cool.

While the focus is on mini excavators, many of these tips also apply to other compact equipment like skid-steer loaders and compact track loaders, which often face similar hydraulic performance challenges under heavy loads.

Why Do Mini Excavators with Attachments Overheat?

Mini excavator overheating occurs when the combined heat from the engine and hydraulic system exceeds the cooling system’s capacity to dissipate it. This risk increases significantly with high-demand hydraulic attachments, especially those that operate under continuous load, such as mulchers, rock grinders, and heavy brush cutters. When the cooling system can’t keep up, temperatures rise quickly, putting both performance and component life at risk.

Key causes include:

- High Hydraulic Demand – Many heavy-duty mini excavator attachments, such as forestry mulchers, stump grinders, and brush cutters, require high hydraulic flow. Running these tools on a standard-flow machine can quickly raise hydraulic oil temperatures. If quick couplers are undersized, they create a restriction, increasing backpressure and generating even more heat.

- Limited Cooling Capacity – Mini excavators have smaller cooling systems than full-size machines. When an attachment requires continuous, high-capacity hydraulic output, especially in hot weather, the radiator and hydraulic oil cooler can be overwhelmed.

- External Temperature and Work Conditions – High ambient temperatures, direct sun, or operating in confined areas reduce cooling efficiency. In these conditions, the radiator may pull in hot recirculated air instead of cooler intake air, further limiting heat dissipation.

- Clogged or Dirty Cooling Components – Dirt, mud, mulch, or sawdust can quickly clog a radiator or hydraulic oil cooler, blocking airflow and trapping heat. This is one of the most common causes of overheating in mini excavators and skid loaders. In severe cases, pressure can build to the point of rupturing the radiator, posing a safety hazard.

- Hydraulic Restrictions – Any bottleneck in the hydraulic circuit—undersized hoses, fittings, or quick couplers not rated for high-flow use—can increase pressure and temperature. Many OEM quick couplers are not designed for continuous high-flow operation, so upgrading to high-flow couplers is critical for running demanding mini excavator attachments efficiently.

Why Overheating Matters

Overheating is one of the fastest ways to cause irreversible damage to a compact machine’s hydraulic and engine systems. Excessive heat degrades hydraulic oil, stripping it of its lubricating properties and allowing metal-to-metal contact inside pumps, motors, and control valves. As oil breaks down, varnish and sludge can form, restricting flow and further increasing system temperatures. Elevated heat also causes seals to harden or swell, leading to leaks, while hoses can soften, blister, and rupture under pressure.

The risks aren’t limited to component wear; extremely hot hydraulic oil can ignite if it leaks onto exhaust manifolds or other hot surfaces, creating a serious fire hazard. Safety shutdown systems may stop the machine before catastrophic failure, but frequent overheating still shortens service life and increases the likelihood of costly, unplanned repairs.

For operators, the impact is twofold: every shutdown means lost productivity in the field, and repeated overheating reduces equipment reliability over time. These principles apply beyond mini excavator attachments — skid steers, compact track loaders, and other compact machines face the same risks when running high-demand tools like mulchers or brush cutters without adequate cooling capacity and properly sized high-flow couplers.

For related insights, see our guide on similar hydraulic challenges in other compact machines:

Prevent Skid Loader Overheating When Mulching

Understanding Hydraulic Flow and Cooling Requirements for Mini Excavator Attachments

Every mini excavator attachment is designed to operate within a specific range of hydraulic flow and pressure. Matching these requirements to your machine’s auxiliary hydraulic system is one of the most critical steps in preventing overheating and avoiding unnecessary wear on components. When the flow is too high, hydraulic oil heats rapidly; when it’s too low, the attachment underperforms, and the system works harder than it should.

- Know Your Machine’s Auxiliary Hydraulic Specs

Start by confirming the auxiliary hydraulic flow rate and pressure output of your mini excavator. These numbers are listed in your operator’s manual and are essential when selecting compatible attachments. Running a high-flow forestry mulcher, for example, on a machine equipped only for standard flow will reduce performance and can also cause excessive hydraulic heat buildup. - Match Attachments to Flow Requirements

Each attachment, whether a trencher, grapple, hammer, or mulcher, has its optimal flow range. Exceeding that range sends more hydraulic fluid through the system than the attachment can efficiently handle, generating heat and potentially damaging seals or bearings. Conversely, running below the required flow can cause cavitation and stress on hydraulic components. - Factor in Continuous Duty vs. Intermittent Use

Attachments used in continuous-duty applications, like brush cutting or mulching, keep hydraulic circuits under load for extended periods. This generates more sustained heat than intermittent-use attachments, such as augers or breakers, which have built-in cooling breaks between cycles. Knowing the duty cycle of your attachment will help determine whether additional cooling measures or high-flow couplers are needed. - Consider Cooling System Capacity

Even when flow and pressure match, your cooling system needs to dissipate the heat generated during operation. Mini excavators with larger oil coolers and higher-capacity fans are better equipped to handle heat from demanding attachments. In high ambient temperatures, operators should monitor coolant and hydraulic oil temperatures closely; many modern machines offer in-cab temperature gauges or warning alarms for this purpose. - Upgrade Hydraulic Couplers for High-Flow Applications

Standard quick couplers often become a flow restriction in high-demand applications. The reduced internal diameter limits hydraulic flow, increasing backpressure and heat generation. Upgrading to high-flow hydraulic quick couplers eliminates this bottleneck, reduces system heat, and ensures your mini excavator attachments operate at peak efficiency.

Properly matching your machine’s hydraulic capabilities to the demands of your attachments and ensuring your cooling system is up to the task goes a long way toward avoiding costly downtime from overheating.

Best Practices to Prevent Overheating in Mini Excavator Attachments

Overheating in mini excavator attachments can often be avoided with a combination of regular inspections, proper hydraulic system setup, and the right components. Consistent maintenance protects your investment and ensures safe, reliable operation in demanding applications.

1. Inspect and Maintain the Cooling System

The cooling system is your first defense against hydraulic and engine heat when running mini excavator attachments. A clean, well-maintained radiator, hydraulic oil cooler, and fan system keep fluid temperatures in check and reduce the risk of costly downtime.

- Check coolant level and quality – Keep the radiator filled to the manufacturer’s recommended level with the specified coolant type. Low or degraded coolant can’t remove heat effectively. Follow OEM service intervals — for example, Bobcat recommends replacing coolant every 1,000–1,500 hours or two years if fluid is rusty, cloudy, or sludgy, flush and refill.

- Use the correct coolant and never mix types – Mixing ethylene glycol and propylene glycol can create a gel that clogs the system. If switching, flush thoroughly first. Many manufacturers color-code coolant to prevent mix-ups.

- Inspect and clean the radiator and oil cooler – Check fins for dirt, dust, or debris. Clean daily in dusty environments or more often when using mulchers or grinders. Avoid bending fins during cleaning, as this reduces airflow and cooling capacity.

- Verify fan operation – Inspect belts for wear and tension, remove debris from the fan, and use reversible features when available to purge dust from the cooler.

- Check hoses, caps, and thermostat – Replace worn hoses, ensure the coolant cap seals properly, and change a faulty thermostat promptly to maintain proper coolant flow.

Regular cooling system maintenance ensures your mini excavator can handle high-demand hydraulic attachments without overheating, protecting your investment and keeping productivity high.

2. Monitor Hydraulic Fluid Condition

Hydraulic fluid plays a critical role in both power transmission and heat dissipation. When oil degrades or becomes contaminated, its ability to lubricate moving parts and carry heat away from the system is reduced — making overheating far more likely. Check hydraulic fluid regularly for changes in color, clarity, and odor. Fresh oil is typically clear or lightly tinted; darkening, a burnt smell, or the presence of metal particles or sludge indicates oxidation, thermal breakdown, or component wear.

Follow your manufacturer’s recommended service intervals for oil and filter changes, but don’t hesitate to service sooner if you notice signs of deterioration. In high-demand applications such as mulching or rock grinding, fluid may require more frequent changes due to sustained high temperatures.

Always use the hydraulic oil type and viscosity specified in your machine’s manual. Using the wrong formulation, such as a lower viscosity oil in high ambient temperatures, can reduce film strength and accelerate heat buildup. Conversely, overly thick oil in cold conditions can cause excessive backpressure and restrict flow, also creating heat. OEM-approved fluids often contain additive packages designed to improve oxidation resistance and thermal stability, which directly supports cooler operating temperatures and longer component life.

If your machine is equipped with a hydraulic oil sampling port, consider routine fluid analysis. Lab testing can detect early signs of contamination, additive depletion, or excessive wear metals, allowing you to correct problems before they cause costly downtime. Keeping hydraulic oil clean, cool, and in specification is one of the most effective and cost-efficient ways to prevent overheating in mini excavator attachments.

3. Match Attachments to the Machine’s Flow and Pressure Ratings

Hydraulic attachments are not one-size-fits-all. Every mini excavator has a rated auxiliary hydraulic flow and pressure range, and every attachment is engineered to perform within its optimal flow window. Mismatching the two is one of the fastest ways to overheat your hydraulic system.

Start by checking your machine’s auxiliary flow specifications, typically listed in gallons per minute (GPM) in the operator’s manual or on the manufacturer’s website. Standard mini excavators often provide 10–20 GPM, while high-flow circuits (common on certain skid steers and CTLs) can exceed 30 GPM. If your excavator has both standard and high-flow options, know which circuit you are connecting to before engaging an attachment.

Likewise, verify the attachment’s hydraulic requirements. Low- to moderate-demand tools such as grading buckets, small breakers, or hydraulic thumbs generally run comfortably within standard-flow capacity. High-demand attachments like forestry mulchers, heavy brush cutters, stump grinders, and large flail mowers require significantly higher flow and continuous duty operation. Running a 30 GPM attachment on a 20–25 GPM machine forces the system to operate at maximum load, generating rapid heat buildup and accelerating component wear.

If your work regularly involves high-flow tools, you may need to upgrade your hydraulic system. Options can include adding a high-flow auxiliary circuit (if supported for your model) or improving the hydraulic path with high-flow quick couplers and auxiliary kits, such as those offered by Stucchi, to reduce pressure drop and heat generation.

Finally, watch your gauges. Rising hydraulic oil or coolant temperatures, warning lights, or alarms are early signs of trouble. At the first indication of overheating, idle the engine with no load to allow cooling before resuming work. Ignoring these warnings can lead to automatic shutdowns or catastrophic component failure.

Operating within your machine’s flow and pressure limits and making auxiliary hydraulic upgrades when necessary is one of the most effective ways to prevent overheating and extend the life of both your equipment and attachments.

View this FREE GUIDE to Mulching and Hydraulics for more information on how Stucchi’s custom hydraulic solutions improve mobile equipment performance when mulching or using high-flow, demanding attachments:

FREE Guide to Mulching and Hydraulics

4. Upgrade Quick Couplers for High-Flow Applications

Quick couplers play a critical role in hydraulic performance, and in many cases, standard OEM couplers are the hidden bottleneck, causing heat buildup. Undersized or restrictive couplers create backpressure, which forces the hydraulic pump to work harder and generates excess heat in the oil. This is especially problematic when running high-flow attachments like mulchers, stump grinders, or heavy brush cutters for long periods.

Upgrading to high-flow hydraulic quick couplers eliminates these restrictions, allowing oil to move freely through the circuit. This not only improves attachment performance but also helps maintain cooler operating temperatures and reduces wear on pumps, seals, and hoses. Stucchi’s high-flow couplers are built for demanding hydraulic applications, providing maximum flow capacity with minimal pressure drop to keep your system running cooler and more efficiently. Whether you operate Bobcat, Caterpillar, Kubota, Takeuchi, John Deere, or other leading brands, Stucchi offers brand-specific coupler solutions designed to integrate seamlessly with your equipment.

For operators looking to boost performance, Stucchi also provides auxiliary hydraulic kits that pair high-flow couplers with components such as adapters, ball valves, and mounting brackets, customized to match your machine’s specifications and the hydraulic demands of your attachments. These solutions ensure a clear flow path, reduce heat buildup, and help your mini excavator run high-demand tools without overloading the system.

When heavy-duty work is on the schedule, upgrading couplers is one of the simplest and most cost-effective ways to protect your hydraulic system and extend equipment life.

5. Keep Hoses and Seals in Good Condition

Hydraulic hoses and seals are the lifelines of your mini excavator’s attachment system, carrying pressurized oil between components. Any weakness in this chain, whether it’s a cracked hose, worn fitting, or failing seal, can lead to leaks, loss of pressure, and increased heat buildup in the system. Heat accelerates wear on hose material, making it softer and more prone to rupture, while escaping oil can damage surrounding components or create a fire hazard.

Hydraulic hoses and seals are the lifelines of your mini excavator’s attachment system, carrying pressurized oil between components. Any weakness in this chain, whether it’s a cracked hose, worn fitting, or failing seal, can lead to leaks, loss of pressure, and increased heat buildup in the system. Heat accelerates wear on hose material, making it softer and more prone to rupture, while escaping oil can damage surrounding components or create a fire hazard.

Inspect all hoses regularly for cuts, abrasions, blistering, or soft spots, especially in areas where they flex or rub against the machine frame. Pay close attention to connection points and seals, which can degrade over time from vibration and thermal cycling. Replace any damaged hoses or worn seals immediately to maintain safe operating pressure and prevent fluid loss.

Pairing quality hoses with leak-free quick couplers, such as Stucchi’s flat face coupler designs, reduces the risk of contamination, protects the environment from spills, and helps maintain steady hydraulic temperatures. Preventive maintenance here not only avoids costly downtime but also extends the life of both your attachments and your excavator’s hydraulic system.

6. Clear Dirt and Debris Frequently

High-demand mini excavator attachments, such as mulchers, brush cutters, and stump grinders, can throw off a constant stream of dust, chips, and other airborne debris. This material can pack into the radiator, hydraulic oil cooler, and surrounding fins, drastically reducing airflow and cooling efficiency. A clogged cooler not only traps heat but can also create dangerous pressure buildup if hydraulic fluid boils inside the system.

To prevent overheating, inspect cooling components multiple times per shift when working in debris-heavy environments, and use compressed air or low-pressure water to clear blockages without bending the fins. For operators running mini excavator attachments daily, frequent debris removal is one of the fastest, most cost-effective steps to keep hydraulic and engine temperatures under control.

7. Operate with Ambient Conditions in Mind

Hot weather and poor ventilation can push your cooling system to its limits, especially when running high-demand mini excavator attachments. On high-temperature days, schedule periodic idle breaks to let the radiator, oil cooler, and fan bring fluid temperatures back into a safe range. Avoid running the machine at full load for extended periods in confined spaces such as between buildings, inside barns, or near snow piles, where hot air can recirculate instead of dissipating.

If possible, plan heavier hydraulic tasks for cooler times of day, and position the machine so prevailing winds or open space can assist with airflow. By aligning your operating patterns with ambient conditions, you’ll help protect your hydraulic system from overheating and extend both attachment and engine life.

Hydraulic Solutions to Prevent Overheating in Mini Excavator Attachments

Running high-demand mini excavator attachments safely and efficiently often comes down to outfitting your machine with the right hydraulic components. Even a perfectly maintained cooling system can’t offset the extra heat generated if hydraulic flow is restricted or mismatched to the attachment’s requirements. Stucchi designs hydraulic solutions that maintain optimal flow, reduce restrictions, and give operators the ability to run demanding tools, such as forestry mulchers, brush cutters, and stump grinders without excessive downtime from overheating.

High-Flow Hydraulic Quick Couplers

When operating attachments that require high hydraulic capacity, standard OEM couplers often become the weakest link in the circuit. Undersized or restrictive couplers increase backpressure, forcing pumps and motors to work harder, which generates more heat. Stucchi’s high-flow hydraulic quick couplers are engineered with precision-machined flow paths and larger internal diameters to minimize pressure drop, allowing hydraulic oil to circulate freely. The result is lower fluid temperature, improved cooling efficiency, and extended life for pumps, motors, seals, and hoses.

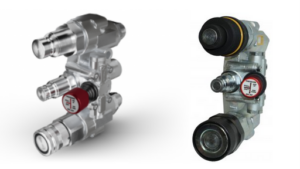

Threaded Flat Face Couplers

Threaded Flat Face Couplers

Threaded flat-face couplers are ideal for high-impulse, heavy-vibration applications where standard couplers may leak or wear prematurely. They provide a secure, leak-free connection that maintains hydraulic system efficiency and helps control operating temperatures. Stucchi’s VEPHD Series, with a locking version, is a heavy-duty threaded flat-face coupler explicitly designed for demanding conditions and high-pressure attachments.

Key VEPHD Specifications:

- Construction: High-grade steel with QPQ plating for corrosion resistance and long service life

- Connection Under Pressure: Capable of connecting or disconnecting with up to 25 MPa (3,625 psi) residual pressure

- Pressure Rating: Operating pressures from 40–55 MPa (5,800–7,975 psi) depending on size

- Sizes: Available in ¾″ to 1½″ with multiple port options for equipment compatibility

- Seal Design: Larger mating faces with a yellow O-ring for quick visual verification of a secure seal

- Performance: Minimizes fluid loss, prevents contamination, and reduces wear on pumps, motors, and seals

This combination of durability, high-pressure capability, and leak-free performance makes the VEPHD an excellent choice for keeping hydraulic circuits running efficiently in the most challenging applications.

Auxiliary Hydraulic Kits for Mini Excavators

Not all mini excavators come equipped with the high-capacity auxiliary hydraulics needed for tools like forestry mulchers or rock grinders. Auxiliary Hydraulic Kits from Stucchi convert compact equipment like excavators, mini-excavators, and skid steers into adaptable, high-flow tool carriers, perfect for running high-demand attachments without risking overheating or downtime. These comprehensive kits ensure that hydraulic systems stay efficient, reliable, and clean under pressure.

Not all mini excavators come equipped with the high-capacity auxiliary hydraulics needed for tools like forestry mulchers or rock grinders. Auxiliary Hydraulic Kits from Stucchi convert compact equipment like excavators, mini-excavators, and skid steers into adaptable, high-flow tool carriers, perfect for running high-demand attachments without risking overheating or downtime. These comprehensive kits ensure that hydraulic systems stay efficient, reliable, and clean under pressure.

Key Features of Stucchi’s Auxiliary Hydraulic Kits:

- Complete Upgrade Packages: Includes everything needed to enhance hydraulic performance, flat-face couplers (APM or A‑HD series), ball valves, hydraulic adapters, and mounting brackets.

- Engineered for Mini Excavators: Specially designed for compact machines to support accessories such as hydraulic thumbs, grapples, breakers, and mulchers

- Auxiliary Diverter Valve Options: For CASE excavators and mini-excavators, kits incorporate two-position, three-way ball valves to effortlessly switch between thumb and attachment circuits without reconnecting hoses

- Brand-Specific Solutions: Custom-fit brand-specific aux kits are available for major OEMs like John Deere, Bobcat, ASV, Takeuchi, and more, ensuring perfect compatibility and seamless integration

- Enhanced in-place Upgrades: Kits like the Saturn Block HD offer field-replaceable, high-flow hydraulic coupler blocks, allowing leak-free, connect-under-pressure swapping even in tight spaces.

By upgrading your mini excavator with a Stucchi Auxiliary Hydraulic Kit, you’ll gain smoother attachment changes, cleaner hydraulic flow, and greater system reliability, especially critical when operating heat-sensitive, heavy-duty tools.

Review this Mulching/Land Management Case Study on how Stucchi improved performance and lowered operating costs for one mulching owner/operator.

Case Study – Mulching and Land Management Solutions

Connect-under-pressure (CUP) Solutions

Hydraulic systems can retain pressure after shutdown, making it difficult to reconnect attachments. Stucchi’s solutions for connecting under residual pressure allow safe, quick reconnections without forcing couplers or risking component damage. This feature is handy for operators who frequently swap attachments in the field.

Hydraulic systems can retain pressure after shutdown, making it difficult to reconnect attachments. Stucchi’s solutions for connecting under residual pressure allow safe, quick reconnections without forcing couplers or risking component damage. This feature is handy for operators who frequently swap attachments in the field.

Stucchi’s hydraulic solutions are designed for maximum durability, efficiency, and operator safety. By upgrading couplers, adding auxiliary hydraulic capacity, and using components built for high-flow applications, operators can run mini excavator attachments with greater confidence, productivity, and reliability.

Keep Your Mini Excavator Attachments Running Cool

Overheating in mini excavator attachments can cause costly downtime, safety hazards, and premature equipment wear, but it’s preventable with the right combination of operating practices, maintenance routines, and hydraulic upgrades. By understanding the factors that lead to heat buildup and equipping your machine with high-quality couplers, auxiliary hydraulic kits, and proper cooling system care, you can keep your mini excavator operating efficiently in even the most challenging conditions. Stucchi’s hydraulic solutions are designed to optimize flow, reduce backpressure, and help operators get the most from their attachments without risking damage or performance loss.

Stucchi has delivered reliable connection solutions for more than 60 years, supporting operators across industries with high-performance hydraulic couplers and kits. We provide custom hydraulic solutions to keep your compact equipment and mini excavator attachments running at peak performance. Contact us today to discuss how our hydraulic solutions can help prevent overheating in mini excavator attachments.