Description

ISO 16028 Interchange

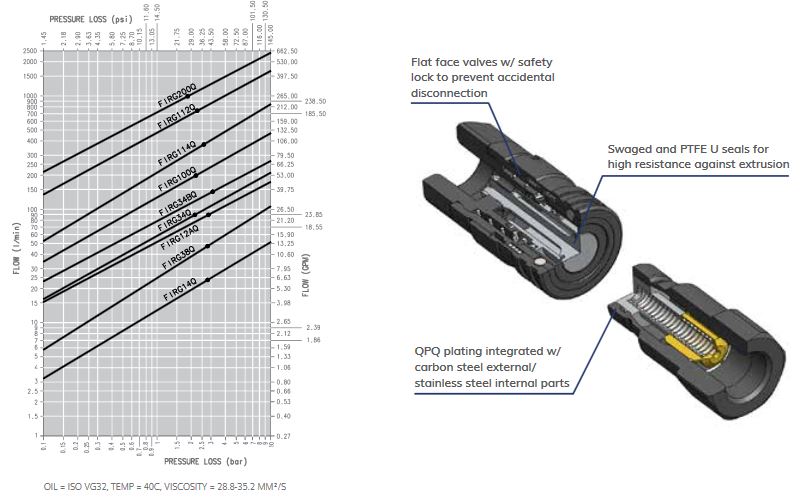

Features

- Size range: 1/4” thru 2”

- Port options: NPT, SAE, BSP

- Interchanges with ISO 16028

- Working pressure: 20-30 MPa/2900-4350 psi range

- QPQ plating treatment for corrosion resistant finish

- Non-spill design avoids fluid loss during connection/disconnection

- Minimal air inclusion during connection

Applications

- Low and medium corrosion environments

- Systems operating on mineral oil, steam, water or other low or medium corrosive fluids

- Steel mills, various industrial process applications, tire manufacturing, state/municipal right-of-way spraying

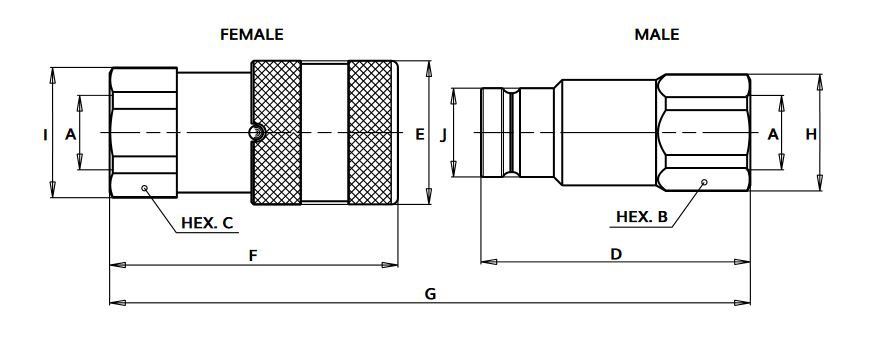

Size Diagram

FIRGQ Series Accessories Coupler Dust Cap | Nipple Dust Cap

| BODY SIZE PORT SIZE | ORDER CODE | DESCRIPTION | ORDER CODE | DESCRIPTION | |

|---|---|---|---|---|---|

| COUPLER / FEMALE DUST CAP | NIPPLE / MALE DUST CAP | ||||

| 1/4 | 1/4 | 815100000 | CAP F. FIRG14/A7 | 815100001 | CAP M. FIRG14/A7 |

| 3/8 | 3/8 | 815100003 | CAP M. FIRG38/A9 | ||

| 3/8 | 3/8 & 1/2 | 815100002 | CAP F. FIRG38/A9/FIRG12 | 815100005 | CAP M. FIRG12/A9 |

| 1/2 | 1/2 | 815100004 | CAP F. FIRG12A/A13 | 815100007 | CAP M. FIRG12A/A13 |

| 1/2 | 1/2 & 3/4 | 815100006 | CAP F. FIRG34/A13 | 815100009 | CAP M. FIRG34/A13 |

| 5/8 | 3/4 | 815100008 | CAP F. FIRG34B/A15 | 815100011 | CAP M. FIRG34B/A15 |

| 3/4 | 3/4 | 815100010 | CAP F. FIRG100/A17 | 815100013 | CAP M. FIRG100/A17 |

| 1 | 1 | 815100012 | CAP F. FIRG114/A21 | 815100015 | CAP M. FIRG114/A21 |

| 1 1/4 | 1 1/4 | 815205020 | CAP F. A25 | 815205021 | CAP M. A25 |

| 1 1/2 | 1 1/2 | 815100014 | CAP F. FIRG112/A30 | 815100017 | CAP M. FIRG 112/A30 |

| 2 | 2 | 815100016 | CAP F. FIRG 200 | 815100019 | CAP M. FIRG 200 |

Additional colors available upon request

Repair Kits

| RDER CODE | DESCRIPTION | |||||

|---|---|---|---|---|---|---|

| FIRGQ SERIES | ||||||

| 815700001 | KIT M. FIRG 14 | |||||

| 815700003 | KIT M. FIRG 38/12 | |||||

| 815700005 | KIT M. FIRG 12A/34 | |||||

| 815700007 | KIT M. FIRG 34B | |||||

| 815700009 | KIT M. FIRG 100 | |||||

| 815700011 | KIT M. FIRG 114 | |||||

| 815700013 | KIT M. FIRG 112 | |||||

| 815700015 | KIT M. FIRG 200 | |||||

![FIRGQ SERIES – QPQ PLATING 1 FIRGQ SERIES – <span class='tooltipsall tooltip_post_id_659 classtoolTips1'>QPQ</span> PLATING<script type="text/javascript"> var tt_store_content = "\<blockquote cite\='https\:\/\/en\.wikipedia\.org\/wiki\/Quench_polish_quench'\>\<b\>Quench polish quench\<\/b\> \(\<b\>QPQ\<\/b\>\) is a specialized type of \<a class\='mw\-redirect' title\='Nitrocarburizing' href\='https\:\/\/en\.wikipedia\.org\/wiki\/Nitrocarburizing'\>nitrocarburizing\<\/a\> \<a class\='mw\-redirect' title\='Case hardening' href\='https\:\/\/en\.wikipedia\.org\/wiki\/Case_hardening'\>case hardening\<\/a\> that increases corrosion resistance\. It is sometimes known by the brand name of Tufftride, Tenifer or Melonite\.\<sup id\='cite_ref\-1' class\='reference'\>\<a href\='https\:\/\/en\.wikipedia\.org\/wiki\/Quench_polish_quench\#cite_note\-1'\>\[1\]\<\/a\>\<\/sup\> Three steps are involved\: nitrocarburize \('quench'\), polish, and post\-oxidize \('quench'\)\.<br/>Source\: \<a href\='https\:\/\/en\.wikipedia\.org\/wiki\/Quench_polish_quench'\>Wikipedia\<\/a\>\<\/blockquote\>"; toolTips('.classtoolTips1',tt_store_content,'659'); </script>](https://www.stucchiusa.com/wp-content/uploads/2018/04/firgq-series.png)